When talking about industrial power supplies, the key word that emerges is “reliability“.

But what exactly does “the reliability of a power supply” mean and how can we improve it?

In this article we explore the importance of this aspect in industrial power supplies, the criteria that determine their robustness and the strategies to optimize it.

The importance of the reliability of a power supply

Reliability is the key to success in the industrial environment. In the context of the power supply, it represents the ability of a power supply to supply energy in a constant and safe way, avoiding interruptions or risks for the devices connected to it.

In corporate contexts, power continuity is essential to keep systems operational and prevent economic losses. Brief interruptions can cause irreversible damage to electronic equipment or completely stop production. That’s why choosing a reliable power supply reduces downtime, prevents failures and protects your investments.

What are the criteria for defining the reliability of an industrial power supply?

To define the reliability of a power supply, a careful evaluation of the specific needs of the application and the environmental conditions in which the device will be used is necessary.

The criteria that define the reliability of a power supply include:

- Complexity of the power module. More complex designs increase the possibility of malfunctions. Simply put, they can affect the safety of the power supply.

- Overcurrent management. The power supply must handle the current correctly to maintain stability. Preventing and therefore being protected from overloads is a crucial requirement.

- Sensitivity to voltage surges. Power supplies are sensitive to voltage variations. Taking preventative measures is essential to protect them from these changes and ensure safe operation over time.

Furthermore, industrial power supplies are critical components subjected to thermal, mechanical and electrical stresses in their operating environments. An analysis of each type of stress highlights:

- Thermal stress. Caused by the high temperatures of both the external environment and those that may occur inside and near the power supply if it is closed in a cabinet or in a metal/plastic container, which may compromise its performance and duration of the components.

- Mechanical stress. Derived from the installation and use of the power supply, it can cause intermittent failures or more serious damage such as dents or cracks in the protection boxes.

- Electrical stress. It occurs when a component operates beyond rated limits, often due to misconfigurations or uncontrolled events, accelerating the aging and early failure of the equipment.

How to optimize the safety of an industrial power supply: factors to consider

To improve and optimize these industrial devices, key strategies must be adopted that embrace several practices, including:

- Anomaly prediction and advanced monitoring. Detecting and predicting irregularities represents a fundamental step in managing a power supply.

- Downgrading management. Choose quality components to carefully design the circuit and reduce decay. In this way it is possible to extend the operational life of the equipment.

- Thermal control. High temperatures can compromise performance and durability. Using advanced cooling technologies and heat dissipation designs can prevent overheating.

- Scheduled preventative maintenance. Periodic inspections and functional tests allow defects to be identified and corrected before they cause malfunctions.

Strategies to improve the reliability of the power supply: from design to adequate installation

The choice of innovative technologies is crucial to ensuring stable operation. To achieve this result it is essential to adopt specific strategies from the beginning design stages up to installation. This will ensure reliable and continuous power supply, minimizing downtime and contributing to the long-term operational success of the industrial plant.

Let’s see them together:

- Rugged design, including solid construction, high-quality components and effective thermal management to ensure reliable performance.

- High quality components, help extend the overall life of the equipment.

- In-depth testing during the production phase, with the aim of identifying and eliminating potential early defects that could compromise reliability.

- Proper installation, which must be carried out by qualified personnel and in accordance with the manufacturer’s specifications and safety regulation.

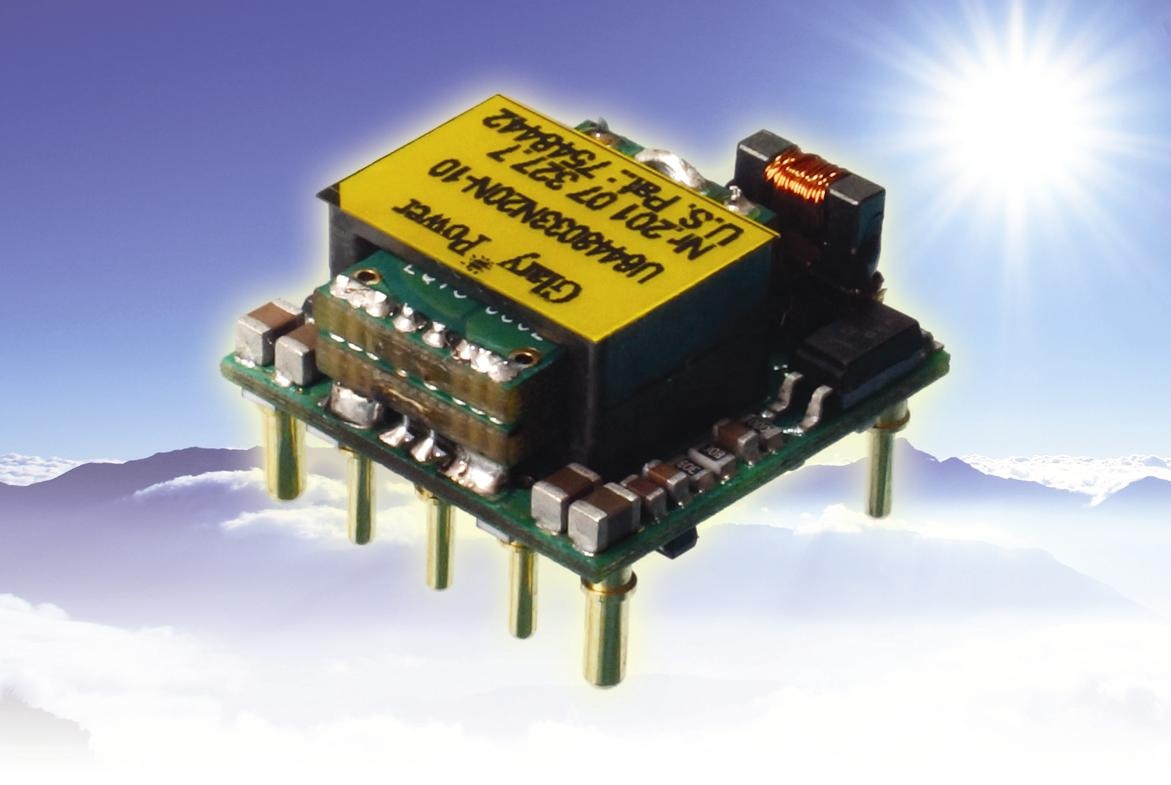

The industrial power supply with eMergy Tech

Here, at eMergy Tech, we are the ideal partner thanks to a complete range of industrial power modules, aimed at maximizing the performance of each system.

Within our catalogue, you can find a selection of AC/DC power supplies from five prestigious brands:

- Vox Power, configurable modules from 150W to 1200W, which let the flexibility to make a power supply with one or more output isolated voltages.

- Selec, modules from 15W to 480W output power.

- Yingjiao Electrical, wide range of products from 6W to 500W.

We do not limit ourselves to being simple distributors: we are committed to providing technical solutions and a personalized consultancy service to meet the specific needs of each customer, ensuring stable and reliable operation of industrial plants.

Find out how we can help you optimize your business with tailor-made solutions!